Ⅰ.Nylon 6 txhaj tshuaj molding txheej txheem

1. Demical thiab lub cev muaj zog

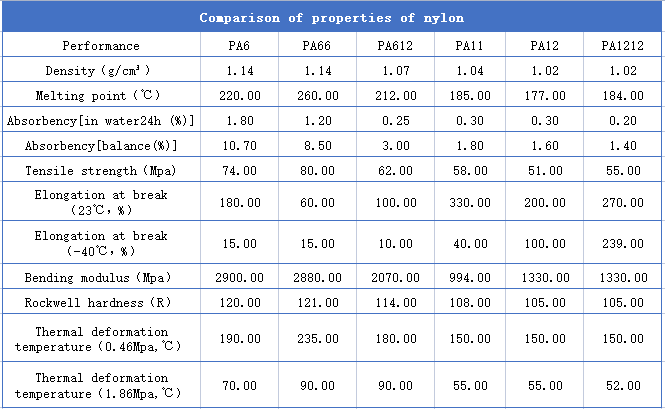

Cov tshuaj thiab cov khoom siv lub cev ntawm PA6 zoo ib yam li PA66; Txawm li cas los xij, nws muaj qhov qis dua melting point thiab cov txheej txheem dav dav dav thiab solubility yog qhov zoo dua li ntawm no ntawm PA66, tab sis nws kuj yog ntau hygroscopic. Vim tias ntau yam ntxwv zoo ntawm cov khoom siv tau cuam tshuam los ntawm hygroscopicity, qhov no yuav tsum tau ua tiav rau hauv tus account thaum tsim cov khoom siv pa6.

Txhawm rau txhim kho cov cuab yeej siv cov khoom siv ntawm PA6, muaj ntau cov hloov kho hloov kho feem ntau ntxiv. Iav yog cov roj hmab ntxiv, thiab qee zaum cov roj hmab hluavtaws hluavtaws, xws li EPDM thiab SBR, ntxiv rau kev txhim kho kev cuam tshuam.

Rau cov khoom lag luam tsis muaj tshuaj ntxiv, PA6 shrinkage yog nruab nrab ntawm 1% thiab 1.5%. Qhov sib ntxiv ntawm fiberglass ntxiv txo qis shrinkage tus nqi rau 0.3% (tab sis me ntsis siab dua ntais mus rau cov txheej txheem). Qhov kev ua kom muaj tus nqi ntawm kev sib dhos molding sib dhos yog feem ntau cuam tshuam los ntawm crystallinity thiab hygroscopicity ntawm cov ntaub ntawv. Qhov tseeb tiag Shrinkage tus nqi tseem muaj nuj nqi ntawm cov qauv yas, phab ntsa tuab thiab lwm yam txheej txheem tsis sib xws.

2.Cov txheej txheem xwm txheej ntawm kev txhaj tshuaj pwm

(1) Kev kho kom qhuav: txij li PA6 Absorbs dej yooj yim, tshwj xeeb saib yuav tsum tau them rau kom qhuav ua ntej kev ua tiav. Yog tias cov khoom siv tau muab tso rau hauv ntim dej tsis muaj dej, lub thawv yuav tsum tau ceev cia airtight. Yog tias cov av noo ntau dua 0.2%, nws raug nquahu kom qhuav hauv cov cua kub saum 80 ° C rau 16 teev. Yog tias cov ntaub ntawv tau raug rau cov pa rau ntau tshaj 8 teev, nws raug nquahu kom nqus dej qhuav nws hauv 105 ℃ rau ntau tshaj 8 teev.

(2) Melting kub: 230 ~ 280 ℃, 250 ~ 280 ℃ rau kev txhawb nqa ntau yam.

(3) Pwm kub: 80 ~ 90 ℃. Pwm kub cuam tshuam rau cov crystallinity, uas nyob rau hauv lem cuam tshuam rau cov khoom siv me me ntawm cov khoom yas. Crystallinity yog qhov tseem ceeb rau cov txheej txheem, yog li cov pom zoo tuaj pwm kub yog 80 ~ 90 ℃.

Rau cov phab ntsa nyias-phab ntsa nrog cov txheej txheem ntev, nws kuj pom zoo kom siv cov khoom siv kub siab dua. Ua kom muaj cov pwm kub tuaj yeem txhim kho lub zog thiab tawv ncauj ntawm cov yas, tab sis txo cov tawv. Yog tias cov phab ntsa tuab yog ntau dua 3mm, nws raug nquahu kom siv cov pwm tsawg-20 txog 40 ℃. Rau cov iav fiber ntau ntxiv txog cov khoom uas tuaj yeem ua kom muaj cov khoom siv txias yuav tsum muaj ntau dua 80 ℃.

(4) Kev txhaj tshuaj siab: feem ntau 750 txog 1250BAR (nyob ntawm cov khoom thiab tsim khoom tsim).

(5) Kev Txhaj Tshuaj Zog: Kev kub ceev (qis dua rau cov khoom siv txhim kho).

(6) Khiav thiab Rooj Vag: Qhov chaw nyob ntawm lub rooj vag tseem ceeb heev vim yog lub sijhawm luv luv ntawm PA6. Rooj vag aperture yuav tsum tsis pub tsawg tshaj 0.5 * t (qhov twg t yog lub tuab ntawm cov khoom yas).

Yog tias siv kub yog siv, lub rooj vag loj yuav tsum muaj me dua li yog siv cov pa uas siv, ua tus khiav kub tuaj yeem pab tiv thaiv cov khoom ua ntej ua ntej ntawm cov khoom. Yog tias lub rooj tog zaum hauv chav dej yog siv, qhov tsawg kawg ntawm lub rooj vag yuav yog 0.75mm.

PA6 Kev Txhaj Tshuaj Moulded khoom

Ⅱn.nyob 66 txhaj tshuaj molding txheej txheem

1.Kom qhuav ntawm Nylon 66

(1) Lub Tshuab Nqus Qhuav: Qhov Kub 95-105 Rau 6-8 teev

(2) cua kub kom qhuav: kub tau 90-100 ℃ txog 4 teev

(3) Crystallinity: Ntxiv rau pob tshab nylon, Nylon crystalline, lub zog muaj zog, hardals expection, hardnal expection, Hardness, tab sis ntawm cov pob tshab thiab cuam tshuam tsis kam. Pwm kub muaj ntau yam cuam tshuam rau crystallization, siab pwm kub siabry siabry, tsis tshua muaj pwm tsawg dua crystallinity.

(4) Tus Nqi Shrinkage: Zoo ib yam li lwm cov khoom lag luam nylon yuav txo cov khoom kub, tab sis cov khoom lag luam sab hauv kev ntxhov siab nce ntxiv kev deformation yooj yim. Shrinkage tus nqi ntawm PA66 yog 1.5-2%.

(5) Cov khoom siv pob zeb: Nylon moulding, lub ntsiab mloog kom tiv thaiv "nozzle flow tshwm sim", yog li kev ua cov khoom nylon feem ntau xaiv tus kheej lub nozzing.

2.Prods thiab pwm

(1) Phab Ntsa Thickness ntawm cov khoom: Qhov ntev piv ntawm nylon cov khoom lag luam yog tsis tsawg tshaj 0.8mm, feem ntau ntawm cov phab ntsa tuab, cov tuab ntawm phab ntsa tuab, qhov ntau dua cov ntsws.

(2) Tso pa tawm: Lub Overflow Rede Resin yog li 0.03mm, yog li lub tshuab nyiam nkauj yuav tsum tau tswj hwm hauv qab 0.025.

(3) pwm kub: cov khoom siv nrog cov phab ntsa nyias nyias yog qhov nyuaj rau tsim lossis xav tau cov khoom siv cua sov pwm, cov khoom muaj qee yam ntawm kev tswj hwm hluav taws xob txias.

Nylon 66 Txhaj Tshuaj Moulded khoom

3.forming Txheej Txheem ntawm Nylon 66

(1. Nylon 66 yog 260 ℃. Vim yog cov neeg pluag thermal ruaj khov ntawm nylon, nws tsis haum rau nyob rau hauv lub tog raj kheej ntawm nyooj, qhov ntsuas kub tshaj nws qhov taw tes ntau tshaj li nws qhov taw qhia sai sai.

(2) Kev Txhaj Tshuaj Siab: Nylon yaj muaj tsawg viscosity thiab zoo fluentity, tab sis kev ua kom nrawm nrawm yog nrawm. Nws yog ib qho yooj yim kom muaj cov teeb meem tsis txaus ntawm cov khoom lag luam nrog cov duab nyuaj thiab cov phab ntsa nyias nyias, yog li nws tseem xav tau txhaj tshuaj ntau dua. Feem ntau lub siab yog dhau lawm, cov khoom lag luam yuav dhau teeb meem; Yog tias lub siab qis dhau, cov khoom yuav khoom noj, npuas, pom muaj cov cim fusion uas tsis txaus thiab lwm yam tsis xws luag. Kev txhaj tshuaj siab ntawm cov ntau nylon ntau yam tsis ntau tshaj 120MPA, thiab cov kev xaiv feem ntau tsis pub dhau ntawm 60-100MPA kom tau raws li cov kev cai ntawm cov khoom lag luam feem ntau. Tsuav cov khoom lag luam tsis tshwm ua npuas, dents thiab lwm yam tsis xws luag, nws yog feem ntau tsis xav kom siv siab dua kev tuav siab. Yog li kom tsis txhob nce sab hauv kev ntxhov siab ntawm cov khoom.

(3) Kev Txhaj Tshuaj Ceev: Rau cov nylon, qhov kev txhaj tshuaj ceev yog nrawm nrawm, uas tuaj yeem tiv thaiv cov ripple tshwm sim los ntawm kev ceev nrawm nrawm thiab tsis muaj teeb meem sib xyaw. Kev txhaj tshuaj sai tau nrawm tsis muaj qhov cuam tshuam tseem ceeb ntawm cov khoom ntawm cov khoom.

(4) pwm kub: pwm kub muaj qee yam cuam tshuam ntawm crystallinity thiab moulding shrinkage. Heev pwm qhov kub thiab txias, hnav tsis kam, hardmas maculus nce, thiab moulding shrinkage ntawm cov khoom nce; Tsis tshua muaj pwm txias, qis siv tau, muaj kuab heev, muaj elongation siab.

4.Nylon 66 Txoj Kev Ua Qauv Txheej Txheem

Lub nraub qaum kub ntawm lub thoob yog 240-285 ℃, qhov kub thiab txias yog 260-300 ℃, thiab qhov kub thiab txias yog 260-300 ℃. Lub Nozzle kub yog 260-280 ℃, thiab pwm kub yog 20-90 ℃. Txhaj tshuaj siab yog 60-200Mpa

Kev siv tus neeg sawv cev tso tawm: Kev siv cov me nyuam tso tawm me me qee zaum muaj cov txiaj ntsig ntawm kev txhim kho thiab tshem tawm cov tsis xws luag. Tus neeg sawv cev tso tawm ntawm cov khoom nylon tuaj yeem xaiv cov roj zinc stearate thiab cov roj dawb, thiab lwm yam yuav tsum muaj kev sib xyaw me me thiab hnav tsis zoo, yog li tsis txhob ua rau pom kev tsis zoo saum npoo. Nyob rau hauv lub shutdown rau nchuav cov ntsia hlau, txhawm rau tiv thaiv cov khoom sib txuas tom ntej, tawg ntsia hlau.

Ⅲ.PA12 Txhaj Tshuaj Kho Moulding txheej

1.Pa12 Txhaj Tshuaj Moulding txheej txheem

(1) Kev kho kom qhuav: Cov av noo yuav tsum muaj kev ua kom qis dua 0.1% ua ntej kev ua. Yog tias cov khoom siv tau rau cov cua cia, nws pom zoo kom qhuav hauv 85 ℃ cov huab cua kub li 4 mus rau 5 teev. Yog tias cov khoom siv tau khaws cia rau hauv lub thawv airtight, nws tuaj yeem siv ncaj qha tom qab 3 teev ntawm qhov kub thiab txias sib npaug.

(2) Melting kub: 240 ~ 300 ℃; Tsis txhob tshaj 310 ℃ rau cov ntaub ntawv nrog cov yam ntxwv tib yam, thiab tsis pub tshaj 270 ℃ rau cov ntaub ntawv nrog cov nplaim taws retardant.

(3) pwm kub: 30 ~ 40 ℃ Rau cov ntaub ntawv tsis tau, 80 ~ 90 ℃ rau nyias-phab ntsa, 90 ~ 100 ℃ rau cov khoom siv txhim kho. Kev ntsuas kub ntau dua yuav ua rau cov crystalloininity ntawm cov khoom. Nws yog ib qho tseem ceeb rau PA12 kom tswj tau yog tswj qhov kub thiab txias.

(4) Kev txhaj tshuaj siab: Txog 1000bar (qis tuav siab thiab zoo yaj yaj kub tau pom zoo).

(5) Kev Txhaj Tshuaj Ceev: Kev kub ceev (nyiam dua rau cov ntaub ntawv nrog cov iav additives).

(6) Khiav thiab cov khoom siv tsis muaj ntxiv, txoj kab uas hla yuav tsum yog 30mm vim muaj viscosity ntawm cov khoom siv. Rau cov khoom siv txhim kho kom tau ntawm 5 ~ 8 hli loj khiav taub. Tus neeg khiav daim duab yuav txhua puag ncig. Lub chaw txhaj tshuaj yuav tsum yog luv li sai tau. Ntau hom GATA cov ntaub ntawv tuaj yeem siv. Cov txheej loj hauv cov khoom loj tsis siv lub rooj vag me me, qhov no yog kom tsis txhob muaj ntau dhau ntawm cov yas lossis ib feem ntau shrinkage tus nqi. GATE Thickness yuav tsum tau sib npaug nrog cov tuab ntawm cov yas. Yog tias lub rooj zaum sov sov tau siv, qhov tsawg kawg plawv ntawm 0.8mm tau pom zoo. Cov tshuab kub khiav kub muaj txiaj ntsig zoo, tab sis yuav tsum tau ua kom zoo kub tswj kom tiv thaiv cov ntaub ntawv los ntawm kev ua kom muaj kev khoo lossis kev ncaj ncees ntawm lub nozzle. Yog tias kub khiav yog siv, cov rooj vag loj yuav tsum yog me dua cov khiav txias.

Ⅳ.Pa1010 txhaj tshuaj cov txheej txheem

Vim tias nylon 1010 molecular qauv muaj cov pab pawg hydrophilic, yooj yim nqus dej noo, nws qhov sib npaug ntawm kev nqus dej yog 0.8% ~ 1.0%. Ya dej muaj cov nyhuv muaj txiaj ntsig ntawm lub cev nqaij daim tawv thiab cov khoom siv ntawm nylon 1010. Yog li, cov khoom siv raw yuav tsum tau qhuav ua ntej siv cov ntsiab lus dej kom tsawg dua 0.1%. Thaum ziab nylon 1010 yuav tsum tiv thaiv oxidation discoloration, vim tias cov pab pawg tau muaj kev nkag siab rau cov pa oxygen oxygen oxygen opadation. Nws yog qhov zoo tshaj plaws kom qhuav ziab thaum ziab, vim tias cov qauv no muaj lub sijhawm kom qhuav thiab zoo huv ntawm cov granules qhuav. Lub tshuab ziab khaub ncaws feem ntau ntau tshaj 94.6 kpa nqus tsev kawm ntawv, 90 ~ 100 ℃ Kub, kom qhuav 8 ~ 12h; Cov ntsiab lus dej poob qis rau 0.1% ~ 0.3%. Yog tias siv cov kev ua haujlwm zoo ib txwm, lub tshuab ziab khaub ncaws yuav tsum tau tswj ntawm 95 ~ 105 ℃, thiab txuas ntxiv lub sijhawm kom qhuav, feem ntau xav tau 20 ~ 24h. Cov ntaub ntawv qhuav yuav tsum ua tib zoo khaws cia kom tsis txhob nqus dej noo.

1.Pa1010 txhaj tshuaj cov txheej txheem

(1) cov txheej txheem yas

Ua ntej nkag mus rau cov pwm kab noj hniav ntawm nylon 1010 yuav tsum tau cov khoom siv ntsuas kub thiab txias, thiab tuaj yeem muab cov khoom siv tsis pub dhau lub sijhawm, molten cov khoom kub yuav tsum yog khaub ncaws. Txhawm rau kom tau raws li cov cai ua saum toj no, ntsia hlau txhaj tshuaj Molding tshuab yog siv raws li cov yam ntxwv ntawm nylon 1010, hom ntsia hlau mib. Lub chrel ntsuas kub nce zuj zus los ntawm Hopper pub taw tes rau pem hauv ntej. Vim hais tias lub barrel ntsuas nyob ze lub suab kub nyob ze lub suab nrov yog pab kom muaj zog ntawm cov khoom lag luam, thiab tuaj yeem tiv thaiv cov khoom siv tsis txaus siab, tso cai rau cov khoom siv kub, cov tawv nqaij kub yog feem ntau 210 ~ 230 ℃. Txhawm rau kom txo cov kev sib txhuam ntawm cov ntsia hlau thiab pa1010 thaum ua kua tshuaj pleev tshuaj, cov nyiaj palaffin, cov nyiaj palaffin tau siv tau los ua cov yeeb yaj kiab 0.5 ~, thiab cov pwm kub yog feem ntau 40 ~ 80 ℃. Qhov nce ntawm rov qab lub siab yog qhov zoo rau kev cog lus nyob rau hauv lub hau ntswj qhov kev xau, tab sis qhov muaj peev xwm ntxiv ntawm kev txhaj tshuaj molding tshuab yog txo. Planizing rov qab siab yuav tsum tsis txhob siab dhau, txwv tsis pub nws txo cov peev txheej ntawm kev ua tau zoo, thiab muaj cua sov ntau, kom cov khoom siv dag zog. Yog li ntawd, nyob rau hauv lub xwm txheej ntawm kev sib ntsib ntawm kev txhaj tshuaj molding, qis dua cov yas yas rov qab los, feem ntau zoo dua, feem ntau 0.5-1.0mpa.

(2) Pwm Sau Txheej Txheem:

Hauv cov txheej txheem no, saib xyuas yuav tsum tau them rau kev txhaj tshuaj siab thiab txhaj tshuaj ceev ntawm nylon 1010 txhaj tshuaj molding. Feem ntau, kev txhaj tshuaj siab yuav tsum 2 ~ 5mpa, thiab kev txhaj tshuaj ceev yuav tsum qeeb. Yog tias kev txhaj tshuaj siab dhau lawm thiab kev txhaj tshuaj nrawm nrawm heev, ces nws yog ib qho yooj yim los tsim cov npuas hauv cov khoom. Raws li cov yam ntxwv hloov ntawm lub siab ntawm cov pwm nqaij, cov txheej txheem kev txhaj tshuaj molding tuaj yeem muab faib ua cov roj hmab ntawm kev pub mis cov pwm, ntws filling thiab txias. Cov txheej txheem cua txias ua tau tuaj yeem faib ua peb theem: siab khaws thiab pub mis thiab ua kom txias dua tom qab ua kom khov.

Qee yam xwm txheej yuav tsum tau ua kom pom tseeb kom paub cov siab tuav thiab cov ntaub ntawv rov ua dua. Ntawm ib sab tes, peb yuav tsum xyuas kom meej tias muaj cov khoom siv molten txaus, uas yog, muaj khoom siv los sau; Nyob rau tib lub sijhawm, lub kaw lus casting tsis tuaj yeem ua tsis tau zoo heev, yog li ntawd cov khoom siv molten muaj txoj kev mus, uas yog ib qho kev tsim nyog rau cov khoom siv. Ntawm qhov tod tes, kev txhaj tshuaj siab yuav tsum tau siab txaus thiab lub siab tuav lub sijhawm yuav tsum tau ntev txaus, uas yog qhov mob txaus rau kev txheeb xyuas cov khoom noj.

Lub sijhawm tuav ib txwm yog txiav txim los ntawm kev sim thiab tsis tuaj yeem ntev lossis luv heev. Yog tias lub siab tuav lub sijhawm yog ntev dhau lawm, nws yuav tsis tsuas yog ncua lub voj voog pwm, lossis tseem tsis tau qhib cov pwm, los sis nws tseem nce kev siv hluav taws xob. Qhov zoo tshaj plaws tuav lub sij hawm yuav tsum tau ua kom muaj qhov seem ntawm cov tuag kab noj hniav yog xoom thaum cov pwm qhib. Feem ntau, cov moulding siab tuav lub sij hawm ntawm nylon 1010 txhaj ntu yog 4 ~ 50 s.

(3) Demoulding:

Nylon 1010 feem yuav yog dab neeg thaum lawv txias hauv pwm kom muaj zog txaus. Qhov kub thiab txias yuav tsum tsis txhob siab dhau, uas feem ntau tswj tau nruab nrab ntawm cov thermal deformation kub ntawm PA1010 thiab puab kub. Thaum demoulding, cov seem siab ntawm cov pwm kab kab hniav yuav tsum nyob ze rau xoom, uas yog txiav txim siab los ntawm lub siab tuav lub sijhawm. Feem ntau, lub sijhawm moulding ntawm PA1010 txhaj ntu yog: Lub sijhawm txhaj tshuaj 4 ~ 20 s, siab tuav lub sijhawm 10 ~ 30s.

Tau qhov twg los: PA nylon muaj saw hlau

Lub sij hawm Post: Mar-09-2023